The IMO Requirement on Tanker Safety and Pollution Prevention, 1978 - Resolution A.446 (XI) 4.4.4.states "means such as level gauges, hand dipping, and stripping system performance gauges as preferred to in Paragraph 4.4.8. shall be provided for checking that the bottom of cargo tanks are dry after the crude oil washing.

Suitable arrangements for hand dipping must be provided at the aftermost portion of a cargo tank and in three (3) other suitable locations unless other approved means are fitted for efficiently ascertaining that the bottom of every cargo tank is dry."

So the simplest method for checking dryness of tank bottom is to lower a Dip-Scale to the tank bottom and read-out the level of remaining oil adhered on the Dip-Scale.

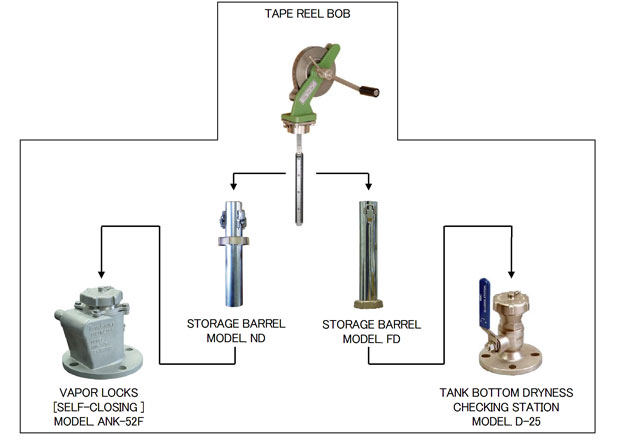

"MMC" Tank Bottom Dryness Checking Device is assembled with a Frame with Storage Barrel, a Tape Reel, and a Handle Mechanism for rotating of the Tape Reel. The Graduated Stainless Steel Tape is wound in the reel, a Dip Scale (Graduated Bar) is fitted at the end of the Graduated Tape.

This arrangement can be used on both Tank Gauging Station [vapor lock] Model. "ANK-52F" [Self-Closing Type] and/or the Tank Bottom Dryness Checking Station Model "D-25" (hand open/closed type), by exchange of Storage Barrel [Hand Dip Adaptor] to avoid releasing dangerous

vapor from tank.